The air ducts - something thats been put low down on our priority list but has always been there. The standard airbox has an inlet that sits just beneath the underside of the fuel tank. On the basis that an engines performance increases if it can breathe more efficiently, then this seems a rather daft place to draw air in.

So we are designing a larger airbox (using the underside of the tank as the top of the airbox) with the air ducts either side of the headstock to help draw the air in from the high pressure point on the front of the bike.

Here's how we are doing it (this will be in several parts as a work in progress and may not be the best way to do it, but is the way we are doing it!) . . .

Above, we have modelled one air duct using MDF and styling clay (quick, easy and the way an Industrial Designer knows how to do it) which fits onto the bike (only one side as the other side will be a mirror image).

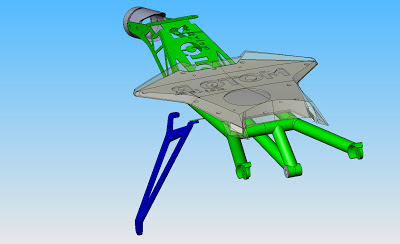

From the clay, we have scanned the part using a FARO Arm and processed it in CAD to give us a 3D representation of the air duct in Solidworks. If we were getting really technical at this stage, we could reverse engineer it into a manufacturable part and do all sorts of flow analysis to optimise the shape - but we didn't.

This 3D model was then sliced in multiple 12mm parts (like a loaf of bread) to give us a number of profiles which could be cut out from MDF and laminated together to create a mold. In fact, there are four molds, one for the top and one for the bottom, then duplicates for a mirrored part to sit on the other side of the bike. (This stage could certainly be sped up by 3D printing or machining the parts from foam, but we always seem to take the hard, less expensive route).

Laminate MDF profiles then gave us these molds, which required a fair bit of sanding and filling, but these will only be used for the first prototype parts, so can still be a little rough. The important thing with these is that they are symmetrical to one another and that both the tops and bottoms fit together.

A close up of the contours. There are a lot of hard points for the air ducts to clear, such as frame tube, fork legs, fairings, light brackets and even stubborn wiring, so they have ended up with quite organic shapes. Once we get to a finish as seen above, we coat them in epoxy resin to give them a hard surface, then a quick sand down to smooth off any high points and its time to lay them up with some fibreglass.

We'll let them cure now, see what happens next in part 2 . . .