The first of our parts to build some more frames have arrived. Above we have the 1 1/4" tubing along with a whole load of lasercut parts. These arrived this morning and were only ordered on Tuesday. We wern't in a rush for them, just great service!

These are the components before bending that will make up three frames and subframes. There are also some additional parts we had made to try to speed up the assembly & welding process as seen below.

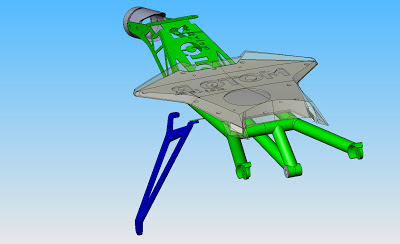

This setup was first seen on a set of Pierobon jigs, where they use lateral jigs to build both sides before final assembly onto the main jig. It looks far easier to hold all the tubing and weld the bosses in place, so following the success of our lasercut swingarm jig and a few hours in Solidworks to model up some jig parts up around our frame, we came up with this setup.

The 1 1/4" tubing drops on perfectly and there are also guides for the smaller diagonals (the red tubes are our old patterns and made to fit 1 3/8 tubing). We look forward to seeing how it goes. Now to await the arrival of the bosses and order some tubing.