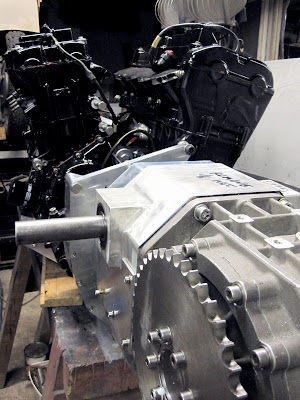

As promised many months ago, a bunch of images showing how the Honda Blackbird crankcases were machined. Two crankcases were machined this time round, allowing Dan to create one of the Dan-tec Square-8 engines he has designed. These images were taken as reference for when the time comes to machine another pair for the spare engine as it was quite a task to get positioned correctly on the milling machine to make multiple cuts without having to reposition. Below is how it went . . .

First cut to clean up the rough edges from when the gearbox was cut off on the bandsaw. Took the surface down roughly to within a few millimeters.

Took the material down to the required depth using a fly cutter, giving a more accurate and cleaner finish.

With the milling machine rotated through 90 degrees, the same process can be applied to the adjacent surface, a rough cut to remove the majority of the material before using a fly cutter.

As you can see here, we were at the very limit of the machines capability of handling the crankcase whilst having clearance in all planes to move the cutter.

Machining away part of the crankcase which needs clearance for one of the main shafts traveling between each crankcase half. This also highlights more problems we had with the machine size, as the cutter had to be operated at an angle to give it clearance to move up and down and not hit the crankcase.

Showing the final cut with clearance.

At this time, to perform the final cut, which was a radius between the 90 degree surfaces, the crankcases had to re-positioned and a cutter on a long shaft used.

Heres the final radius between both surfaces.

Whilst all this was going on, the aluminium base plate had been machined at Bosal and was delivered, ready for the freshly machined crankcases to be bolted on.